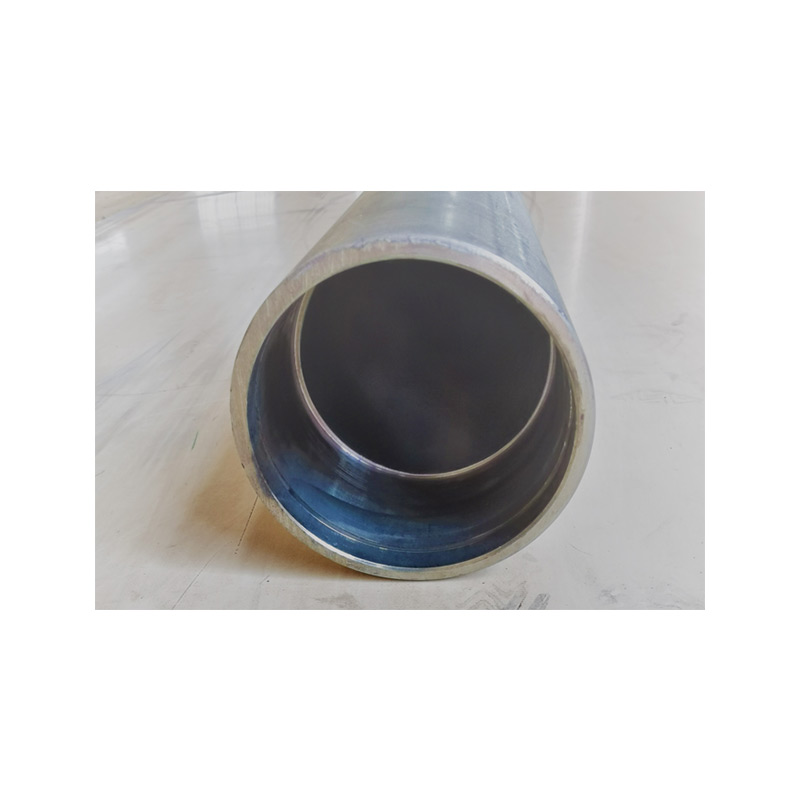

Tensioning rollers are widely used in various transmission and conveying systems and sorting and conveying equipment such as express delivery, logistics, mining conveying equipment, paper making and packaging machinery. The belt conveyor can be formed by a set of belts with power device, conveying coal, sand, sack, equipment and other objects; it can be used in various ways by conveying objects with flat and hard bottom side side side by side. The diameter is mainly 102mm, and the length is 560mm, 660mm, 860mm, 1060mm, 1260, 1460mm, etc. We can also customize various specifications of rollers according to customers' requirements. The head and tail rollers are mainly composed of barrel body, core shaft, bearing and spring. The barrel body is made of high quality seamless tube and the core shaft is made of high quality carbon structural steel, which has greater strength; the bearings are preferably selected to ensure the performance and life of use; the bearings are installed by pressing in, which is a compact fit; the end of the core shaft is connected to the body using threads.

Role

1.To ensure that the conveyor belt has enough tension at the winding out end of the drive roller, so that the required traction force is transmitted to prevent the belt from slipping.

2.To ensure that the tension at each point of the conveyor belt is not lower than a certain value, so as to limit the drape of the conveyor belt between the rollers and prevent the spreading of material and the increase of resistance to movement.

3.Compensate the plastic elongation of the conveyor belt and the change of elastic elongation under the transition working condition.

4.Provide the necessary travel for belt rejoining.

Performance advantages

1. Flexible rotation, no running noise. The roller has large bearing capacity.

2. The end of the roller used with the belt has a slope, which increases the friction, and the belt is not easy to slip.

3. The surface can be galvanized, beautiful and rust-proof.

4. Not high requirements for the use environment, high and low temperature can be good operation.

5. Compact structure, less occupation, high reliability.

6. Easy to use and maintain, safe and reliable operation, long service life.

Kunming Yuanshi Machinery Equipment Manufacturing Co., Ltd. is located in Kunming City, Fumin County, Sentinel Industrial Zone, 38 km from downtown Kunming, is an investment project in Fumin County in 2009, the company covers an area of 12,200 square meters, obtains real estate rights certificate area of 10,002 square meters, the actual investment of 32 million yuan, the construction of two standardized industrial plants 4320 square meters, standard staff accommodation 1 building 3500 square meters, supporting Staff canteen 360 square meters, independent research and development office 1 building 1700 square meters, various types of production equipment 8 million yuan, with independent property rights for 50 years of machinery and equipment manufacturing Co. Our company has more than 30 years of experience and technical accumulation in this industry, the level of people, machines, materials and work can undertake the processing of small and medium-sized various parts, components of manufacturing and assembly, etc. for one-stop service. Our company is based on the principle of "visionary, honest and pragmatic", and we are looking forward to the development and future together with all the knowledgeable people. Value concept: integrity and pragmatism, unity and progress, cooperation and win-win; Quality policy: professional technology to provide quality products, so that customers can rest assured that the choice; Survival philosophy: hard work and dedication, hard work and dedication, create and share.

Wang Qinghua

531947875@qq.com